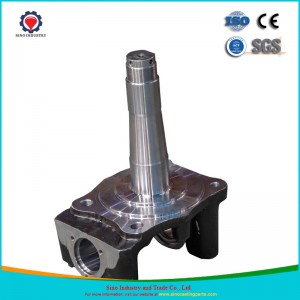

Customized Auto Parts by ISO9001 OEM Factory for Steering Knuckle

Product Details

| Item | Steering Knuckle |

| Surface Roughness | Ra0.05∼Ra50, depends on Customer’s Requirements |

| Process | Mold Making, Casting, Machining, Surface treatment, Inspection, Packing, Loading |

| Casting tolerance | CT5-CT8 |

| Casting blank size | 2mm-1500mm or according to customer's requirement |

| Casting blank weight | 0.01kg-3000kg |

| Coating | Electrophoresis Coating |

| Machining | Lathing/Milling/Turning/Boring/Drillig/Tapping/Grinding, etc |

| Machining tolerance | 0.01mm |

| Certification | ISO9001:2015, CE, SGS, RoHS, IATF16949 |

| Application | Automobile, Heavy truck, Light Truck, Commercial Vehicle , Forklift, Train, Railway, Tractor, Trailer, Passenger Bus, etc. |

| Package | Bubble plastic bag/polybag/pallet/wooden case, etc. |

| Trademark | OEM |

| Origin | China |

| Loading Port | Qingdao Port |

| Annual Supply | 3000000 Pieces |

| Sample | Available |

| Sample production cycle | 30-45 Working days. |

| OEM/ODM service | Available |

Steering Knuckle products Introduction

The steering knuckle is one of the important parts in the steering axle of the car, which makes the car run stably and transmit the driving direction sensitively. It transmits and bears the front load of the car, supports and drives the front wheel rotating around the kingpin for turning the direction. In the car driving condition, it bears the changeable impact load. Therefore, it is required to have high strength. Our company inherits previous technology accumulation, and developed the most advanced concept of forging, heat treatment, machining and inspection, which has high compatibility.

We can produce all disc and hub steering knuckles with shaft diameters of Φ35 - Φ80, covering passenger cars and commercial vehicles. For the disc steering knuckle, the shaft diameter and the brake caliper plane are processed at one time in our turning and milling center, which ensures the coaxiality of the inner and outer shaft diameters and the verticality and flatness of the brake jaws. The raw materials are 42CrMo steel, High grade product quality is effectively guaranteed.

Our Steering Knuckle Range

(1). 9.5 Ton hub type and disc type for commercial vehicles

(2). 7.5 Ton hub type, disc type

(3). 6.5 Ton hub type, disc type

(4). 5.5 Ton hub type, disc type

(5). 3.5 Ton hub type, disc type

(6). Pickup steering knuckle

(7). Special steering knuckle for mining equipment/machines.

Our Products and Competitive Advantages

We customize various sizes of steering knuckle, leaf spring bracket, bumper bracket, engine bracket, balanced suspension, steering gear bracket, as per customer's requirements. All above mentioned products are used on truck, heave-duty truck, lorry truck, transportation vehicle, forklift, farm/agricultural vehicle/machinery/machine/truck, combine harvester, tractor, trailer, dump truck, mining equipment/ machinery/ machine/ truck/ vehicle, industry/ industrial machinery/ machine/ equipment/ device/ facility, bus, passenger bus, coach bus, shuttle bus, passenger car, tourist bus, sightseeing car, pickup truck, school bus, cargo trailer, special vehicle, trailer truck, dumper truck, etc.

The castings produced by us are widely used in various industries,such as construction vehicles, trains, railways, forklifts, agricultural machinery and other mechanical equipment. We can produce all kinds of castings according to customer's drawings and customer's requirements.

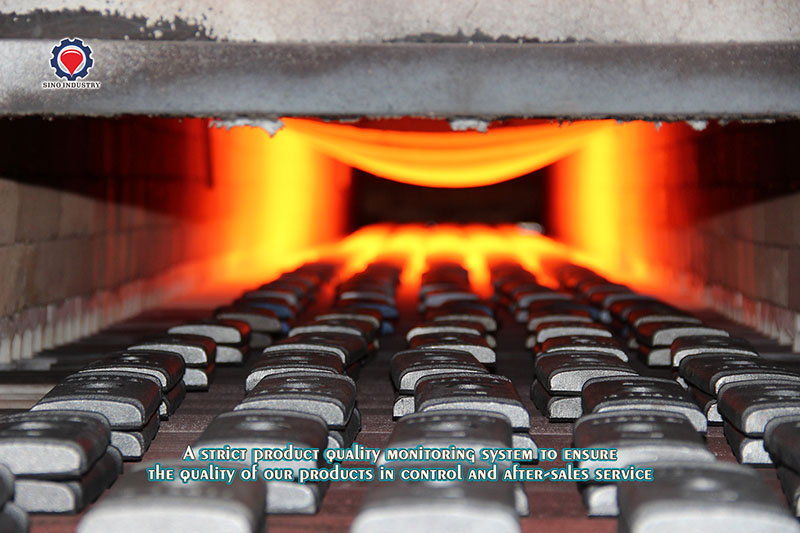

We own advanced production lines, testing equipments and measurement equipments. A senior engineering technical team with special skills and rich experience for over 40 years in product design, casting, forging and machining fields. Have special technology and skill to solve and handle special material, special structure, special defect and special processing. 800 skilled employees, 50 management personnel, 60 senior technical engineers and 60 quality inspectors. We have more than 400 sets of casting/forging/machining equipments in total, including 60 sets of four/five-axis machining center (CNC) and 2 sets of digital special machines designed with double main axle boxes. We have two lines of forging production equipments with 8000 ton/4000 ton friction press machines, 4000 ton/2500 ton electric screw press machines. There are two sets of heat treatment production lines, 6 sets of machining production lines, with an annual output of 600,000 sets of steering knuckles.

Our testing equipments: photoelectric direct reading spectrometer, three-coordinate measuring instrument, high-frequency infrared carbon and sulfur analyzer, digital Rockwell hardness tester, metallographic microscope, roughness detector, roundness detector, tensile testing machine, magnetic particle inspection machine etc.

Our company has passed the ISO9001 and ISO16949 quality management system certification. We provide customers with top-grade quality products. We are the original parts supplier of China famous brands of heavy trucks, large mining equipment and medium/large passenger buses factories.

FAQ

Q1. Are you a factory or trading company?

We are a factory integrating research, development, production and sales. A professional manufacturer specializing in the design, development, manufacture and marketing in the foundry industry for more than forty years. We are a source manufacturer, our products have a considerable price advantage relative to intermediary traders. We have a complete production line, all production links from raw materials to finished products are under our control.

Q2. What are the advantages of your products?

We support product customization to meet customer needs for special products. We can strictly control the products from raw materials to production, processing, product quality inspection, delivery, packaging, etc., and provide customers with high-end products and the most advantageous prices.

Q3. How about the price?

We are a factory, all products are direct sale at factory price. For the same price, we will provide the better quality; for the same quality, we offer more advantageous price.

Q4. What is your terms of packing?

We have branded packaging and neutral packaging, and we can also do what you want with authorization. its flexible and negotiable.

Q5. How can I get a formal quotation from you?

Please send us the technical drawings upon which we will offer you a formal quotation accordingly.

Q6. Do you accept third party inspection?

Yes, Inspection agency can be appointed by buyer.

Q7. How about your delivery time?

Generally, it will take 3 to 10 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order. In addtion, our factory possesses geographical superiority-its only one and a half hours’ drive from our factory to the nearest shipping port-which makes our delivery system more efficient.

Q8. What is your terms of payment?

By TT or LC. We'll show you the photos of the products and packages before you pay the balance.